Description

Click here to view the Technical Data Sheet for Novoplan Easy Plus

FEATURES AND BENEFITS OF NOVOPLAN EASY PLUS

• For leveling, smoothing and repairing interior floors

• Ready for tile in 24 hours

APPROXIMATE COVERAGE

| Thickness |

Coverage |

| 1/4″ |

24 sqft |

| 1/2″ |

12 sqft |

| 3/4″ |

9 sqft |

| 1″ |

6 sqft |

INDUSTRY STANDARDS AND APPROVALS

• Meets compression and flatness requirements of ASTM F710, Standard

Practice for Preparing Concrete Floors to Receive Resilient Flooring

• Meets compression and flatness requirements of ASTM F2873, Standard

Practice for the Installation of Self-Leveling Underlayment, and the Preparation

of Surface to Receive Resilient Flooring

Green certifications

• Living Building Challenge (LBC) Red List Free: This product has been

verified per the most current Red List on the LBC’s Website.

WHERE TO USE

• For leveling, smoothing and repairing of interior residential or commercial

floors before the installation of floor coverings

• For use over radiant-heated floors or to encapsulate hydronic or electric

radiant-heated floors

LIMITATIONS

• Do not mix with other self-leveling underlayments.

• Do not install over unprimed surfaces.

• Do not install over flooring products, adhesive residues or substrates

containing asbestos.

• Do not use for exterior applications. For interior use only.

• Do not apply Novoplan Easy Plus unless the substrate temperature is

maintained at between 50°F and 90°F (10°C and 32°C) for 48 hours

before, during and after application. Do not allow freshly installed

Novoplan Easy Plus to freeze.

• Do not use as a final wear surface. Cured Novoplan Easy Plus must be

covered with a finished floor system or floor covering.

• Do not install over standing water.

• Do not install over dimensionally unstable materials.

• Do not install if the maximum allowable deflection of the supporting surface

exceeds L/360 (or L/720 for installations involving natural stone or their

agglomerates) when exposed to live or dead loads.

• Do not use in areas subjected to prolonged exposure to moisture. Contact

MAPEI’s Technical Services Department for waterproofing recommendations.

• Do not use as a moisture mitigation product. Cement-based self-leveling

underlayments do not reduce moisture vapor transmissions emanating

from high-humidity concrete slabs. If the flooring or installation system

requires protection from elevated humidity levels, moisture mitigation must

be done before Novoplan Easy Plus is installed. Contact MAPEI’s Technical

Services Department for recommendations regarding moisture mitigation

SUITABLE SUBSTRATES

• Concrete that is installed in compliance with ASTM F710,

that is at least 28 days old, and that is free from hydrostatic

pressure, osmotic blistering and alkali silica reaction

• Well-bonded and dimensionally stable ceramic tile,

porcelain tile, quarry tile, natural stone, vinyl composition

tile (VCT), cement, epoxy-based moisture barriers and

epoxy terrazzo

• Properly installed cement backer units

• Durable and fully cured cement-based mortar beds

• Engineer-approved plywood and oriented strand board

(OSB) subfloors with a maximum of 19.2″ (48.77 cm)

on center joist placement and that meets requirements

of L/360

• Nailed-down wood flooring (including plank wood

subfloors, strip wood subfloors and nailed-down solid

wood flooring) that has been covered over with at least

one layer of 5/8″ (16 mm) plywood, glued and screwed

• Gypsum-based underlayments

• Mapeheat ™ Membrane, Mapeguard ® UM and similar

crack-isolation and uncoupling membranes (these do

not require priming)

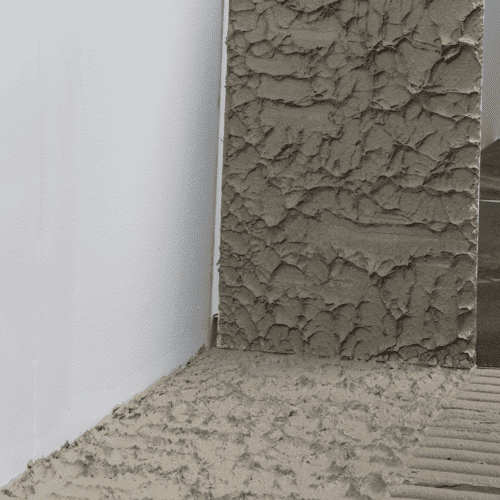

SURFACE PREPARATION

• All substrates must be properly prepared, structurally

sound, stable, solid, dry, and primed with an appropriate

MAPEI primer unless otherwise noted.

• On concrete substrates, fill in deep areas, holes and

cracks with an appropriate MAPEI patching compound

or screed. Fluid self-leveler may leak through to a floor

below or other unwanted cavities.

• On plywood substrates, fill joints with an acrylic-based

caulking compound to prevent the underlayment from

leaking into a floor below.

Refer to MAPEI’s reference guide “Surface-Preparation

Requirements for Self-Leveling Underlayments” for details

on proper surface preparation.

MIXING

Before product use, take appropriate safety precautions. Refer to the Safety Data Sheet for details.

- Based on the number of bags to be mixed, measure and pour the required amount of water (see “Mixing ratio” in the chart below) into a clean mixing vessel such as MAPEI Self-Leveling Mixing Barrel or a plastic pail that can hold at least 5 U.S. gals. (18.9 L). For best results, the water temperature should be at about room temperature (70°F or 21°C). The mixing ratio must remain consistent; do not overwater the mixture.

- Slowly add the powder into the pre-measured water, taking care to not generate excessive dust. Use a high-speed drill and an oval paddle mixer to mix Novoplan Easy Plus to a homogenous, lump-free consistency.

- Continue to mix for 2 to 3 minutes. Do not overmix: Overmixing or moving the mixer up and down during the mixing process could trap air or cause pinholing during the application and curing process.

PRODUCT APPLICATION

Read all installation instructions thoroughly before installation.

- Substrates and ambient room temperatures should be maintained at between 50°F and 85°F (10°C and 29°C) during application as well as for 3 days before and after application.

- Before product installation, close doors and windows, and turn off HVAC systems to prevent drafts during application and until the underlayment is cured. Protect installation areas from direct sunlight.

- Quickly pour or pump mixed self-leveling compound onto the surface in a ribbon pattern. Set the width of the pour at a distance that is ideal for maintaining a wet edge throughout placement. For best results, work as a team to provide a continuous flow of wet material, to avoid trapping air or creating a cold joint. Apply enough material to adequately cover all high spots.

- Shortly after placing Novoplan Easy Plus, use a gauge rake to spread the material and assist in gauging it to the desired depth. After achieving the desired depth, use a smoother to obtain an even surface.

CURING

• Novoplan Easy Plus is self-curing. Do not use a dampcuring method, or curing and sealing compounds.

• Cool-weather conditions may extend curing or setting

times. Warmer weather conditions may accelerate

working, curing and setting times.

CLEANUP

• Wash hands and tools with water promptly before the material hardens. Cured material must be mechanically removed.

PROTECTION

• Protect Novoplan Easy Plus from direct sunlight, excessive heat and drafty conditions during curing. Turn off all forced ventilation and radiant heating systems, and protect the installation for up to 24 hours after completion.

• Avoid walking on the installed surface for at least 2 to

3 hours after installation, depending upon temperature and humidity conditions.

• Protect the installation from traffic, dirt and dust from other trades until Novoplan Easy Plus is completely cured and final flooring has been installed.

• Do not expose Novoplan Easy Plus to rolling dynamic loads, such as fork lifts or scissor lifts, for at least 3 days after installation.